More new therapeutic treatments for various diseases could be moved into clinical trials—and potentially faster into mainstream medical use—if scientists could find ways to manufacture exponentially higher quantities of the stem cell components needed for medical testing.

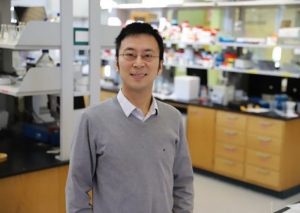

Spearheading work to make those cell manufacturing process discoveries is Associate Professor Zhen Ma, the Carol and Samuel Nappi Research Scholar in the College of Engineering and Computer Science. He is working with a newly awarded $500,000 National Science Foundation (NSF) future manufacturing seed grant and coordinating the project with bioengineering experts at the Rochester Institute of Technology (RIT).

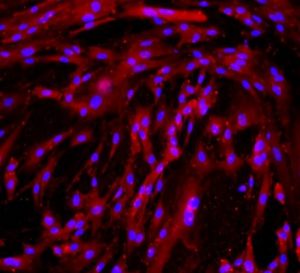

Ma’s project is examining new ways to ramp up the quantity of extracellular vesicles (EVs), produced from mesenchymal stem cells that can be manufactured in a lab to meet the therapeutic critical need for biological products. The cells have the ability to use EVs to communicate with other cells by transferring proteins, lipids and nucleic acids using EVs as a compartment. EVs produced by mesenchymal stem cells can inhibit inflammation, modulate immune responses, reduce cell die-off, and enhance tissue repair and regeneration.

At present, EV manufacturing capacity remains far below desired needs, according to Ma. “We are currently at the beginning stage, in that engineers can manufacture perhaps a hundred thousand cells in a lab, although the capacity needed to scale-up production of more than one million cells a day is the level needed to bring EV use to bear in the clinical trial stage,” he says.

With the NSF future manufacturing seed grant, Ma and his research partners are looking to boost EV production in what would technically be described as integrating human induced pluripotent stem cells for scalability in the donor cell source, genome engineering for scalability in EV biogenesis and advanced nano-membrane technology for scalability in EV purification. It is a project that can be potentially transformative in EV biomanufacturing due to several technological advances that would improve not only the scalability but the consistency and therapeutic potency of next-generation EVs, Ma says.

Partnering With RIT

The project is unique because of its cross-disciplinary, multi-institution nature, as well. As principal investigator on the project, Ma is partnering with co-principal investigators affiliated with RIT. They are Thomas Gaborski, professor and director of RIT Biomedical and Chemical Engineering Ph.D. program, and Karin Wuertz-Kozak, Kate Gleason Endowed Full Professor of biomedical engineering and director of the Tissue Regeneration and Mechanobiology Lab at RIT. Also involved is Aslan (Mehdi) Dehghani, lead extracellular vesicle (EV) scientist and bioengineer in the Corporate Research team of Sartorius Stedim North America, one of the largest global biotechnology firms. The company provides solutions to biopharmaceutical industries and laboratories to simplify and accelerate progress in bioprocessing. Dehghani, current collaborator and former trainee of Gaborski, will provides his expertise in EV purification to this collaborative project.

Ma says that in addition to the immediate effort to find ways to boost levels of manufacturing EVs in labs, the team also has a longer-term goal. That is to gain a fundamental understanding of the biogenesis process, regulatory mechanism, physiochemical properties and biological functions of EVs to further advance the biomanufacturing of therapeutic EVs from various stem cell types. That work calls for new expertise in EV biology, bioreactor design, biomanufacturing processing and quality controls.

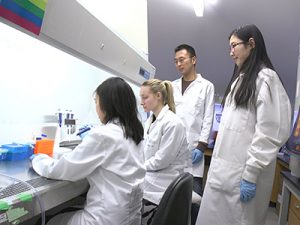

Courses and Internships

In addition to the research aspects of the initiative, the team’s work is designed to benefit graduate and undergraduate students who are studying and working in the labs at both academic institutions. Those goals are being achieved by the development of new courses to be conducted jointly at both Syracuse University and RIT campuses, and by leveraging existing programs at both institutions for outreach activities, Ma says. The close industrial collaboration the project creates with Sartorius Stedim North America will also present industry internship opportunities to graduate students, he says.

Ma’s expertise focuses on stem cell engineering, cardiac tissue engineering and 3D organoid technology. In his research lab, he is working on improving the diagnosis and treatments used for human heart diseases. His research includes developing next-generation cardiac organoid models through the combination of stem cell biology, micro/nanotechnology and artificial intelligence. He earned bachelor’s and master’s degrees at Tianjin University and a Ph.D. at Clemson University, and did postdoctoral work at the University of California, Berkeley, before coming to Syracuse University.

By Diane Stirling