More than 106,000 Americans are waiting for a lifesaving organ transplant, with a new name added to the list every nine minutes. The demand is critical, explains Syracuse University professor Pranav Soman, and includes people of every age, gender, race and ethnicity. “There are as many people dying from organ disease as those needing a transplant. It’s a huge public health issue,” he adds.

Soman hopes that his work in the College of Engineering and Computer Science will save lives. The award-winning researcher is renowned for his contributions to 3D bioprinting—a new field in which organic and biological materials combine to create artificial structures that imitate human cells and tissues. His goal is to print a fully biocompatible 3D organ.

To achieve this, Soman has developed a technology toolbox for 3D bioprinting. Unlike 3D printing (which outputs materials like plastics, ceramics and metals), 3D bioprinting relies on bioinks—cell-laden substances that can be manipulated to print 3D structures used in applications like medical, hearing loss and dental implants; artificial joints; and nerve-stimulating devices.

“Bioprinting is the future of organ transplantation,” declares Soman, who joined the biomedical and chemical engineering faculty in 2013.

Like Yin and Yang

A steadfast experimentalist, Soman thrives on direct experience and empirical evidence. His work owes a debt, however, to Chris Santangelo, a renowned theoretical physicist in the College of Arts and Sciences. The two are like yin and yang, representing different paths to the same goal in biomaterials research.

Santangelo came to Syracuse in 2019 with expertise in tiny nonbiological objects, including origami and self-folding materials, mechanical metamaterials, and liquid crystals. “I look at how these materials change shape and function, in response to stimuli like heat or moisture,” he says, adding that his work has been used to create biomaterials that help with hemorrhage control and collapsible origami structures that keep arteries open.

A member of the College’s Soft and Living Matter Group, Santangelo acknowledges the link between pure math and physics. Much of his research draws on geometry and topology (the study of properties preserved through the deformation, twisting and stretching of objects). One technique that Santangelo uses is DNA origami, in which long strands of DNA are computationally folded into arbitrary patterns. The procedure enables him to design nanostructures, like in vivo biosensors and drug delivery containers, in a matter of weeks.

Owning the Research Experience

The interplay of theory and experiment is on full display in the University’s BioInspired Institute, where Santangelo and Soman oversee the Smart Materials interdisciplinary research group. Working with scientists from different fields and institutions (including SUNY Upstate Medical University and SUNY College of Environmental Science and Forestry), the duo aims to replace or repair body parts damaged by age, disease or trauma.

Zachary Geffert, a Ph.D. student in bioengineering, compares Santangelo and Soman to an architect and an engineer, respectively. “Let’s say the architect has an idea for an application or a problem to be solved. He talks to the engineer, who, in turn, sets up a realistic experiment within the capabilities of what is state-of-the-art,” says Geffert, who is training for a career in bioprinting. “If these capabilities aren’t up to par, Professor Pranav blows them out of the water with something new.”

Speaking from his lab in Bowne Hall, Soman smiles at the mention of rich, interdisciplinary exchange. “BioInspired organizes seminars and brainstorming sessions—anything to get people from different backgrounds working together,” he says. “We want students to own the research experience.”

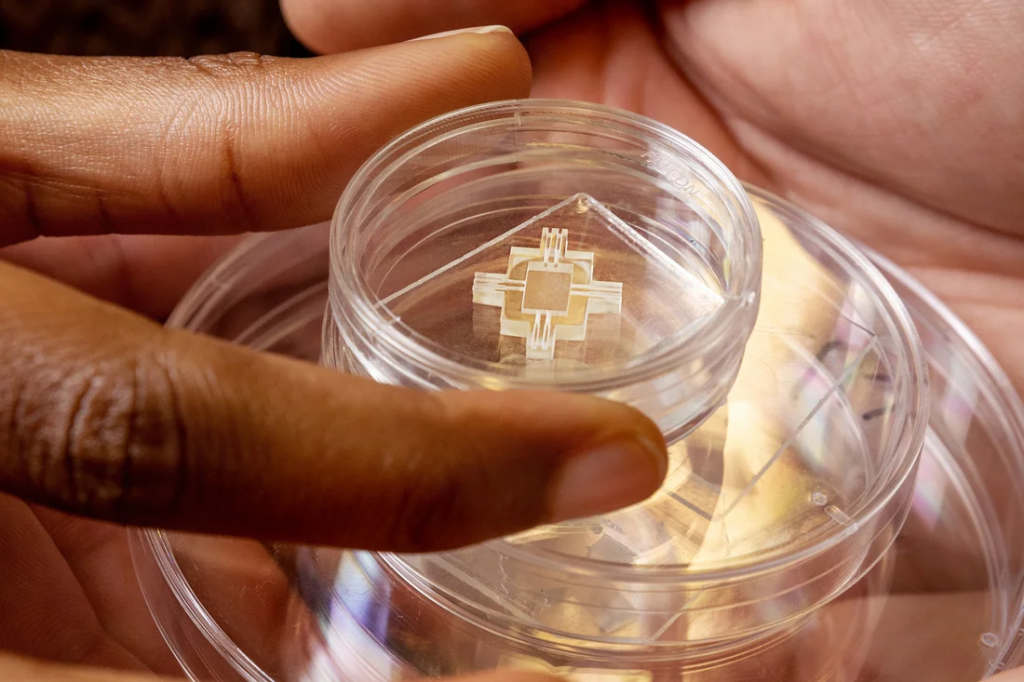

One of Soman’s Ph.D. students is Anna-Blessing Merife, who helps faculty at SUNY Upstate print 3D microfluidic devices for eye and bone tissue. (Microfluidics deals with fluid mechanics, often at volumes thousands of times smaller than a common droplet.) “The field has major implications for drug development, disease modeling and personalized medicine,” says the aspiring professor. “Thanks to BioInspired, I’m achieving my career goals.”

Acting Entrepreneurially

Soman is taking microfluidics to the marketplace with his company, 3D Microfluidics, which he founded with former student Zheng Xiong G’21. The company’s technology provides applications in multiple areas, including fundamental cell biology, drug screening, cellular therapy, toxicity testing and regenerative medicine. Microfluidic chips, which simulate organ function at the micro and nano levels, also are on the horizon.

Moreover, Soman’s interest in 3D ceramic printing has led to a partnership with the Wright-Patterson Air Force Base in Ohio, where he was a 2022 summer faculty fellow. While not as easy to shape as metals and plastics, ceramic materials are known for their unique properties. “Ceramics are perfect for portable electronic devices because they’re durable and heat resistant,” says Soman, who works alongside Geffert. “They also offer excellent electrical insulation.”

Adds Geffert: “Working with Professor Soman allows me to do what I’m good at—be an engineer and solve problems. He inspires me to explore the unknown.”

Succeeding Responsibly

Like Soman, Santangelo draws on BioInspired’s collaborative ethos to fast-track novel ideas. Some have garnered generous support from the National Science Foundation (NSF), National Institutes of Health and Department of Defense.

One of his projects involves colleagues from Syracuse, the University of Pennsylvania and the University of Colorado Boulder. The NSF-backed team is using soft, malleable materials to create a robotic bed. “Turning a patient in bed is one of the most dangerous jobs in a hospital,” says Santangelo, noting that nursing staff injuries, like sprains, strains and tears, cost the U.S. healthcare industry about $9 billion a year. “We’re designing a surface that can dynamically change shape, allowing patients to be easily repositioned.”

That’s what Santangelo likes about his job—working with equations that are immutable. “The beauty of being a theorist is that it’s always the same math, the same geometry, the same physics. I just apply the principles differently,” he says. “I use a surprising amount of high school geometry.”

Differential geometry, the study of smooth shapes and spaces, figures prominently in his foray into flexible electronics. Think ultrathin wearable devices; artificial skin and muscles; and soft, deformable robots. Surprisingly, flexible electronics are not too far afield from centuries-old mechanical computing.

“Some of these concepts—like simple logic, which is at heart of mechanical computing systems—are making a comeback in soft materials,” says Soman, referring to matter that’s easily deformed by thermal stresses and fluctuations. “For instance, a body temperature sensor is nothing more than a simple computer. It doesn’t need technically sophisticated chips and software. Why consume large amounts of power and put chemicals in your body when you don’t have to?”

Santangelo and Soman agree that it’s not enough to make easy-to-use products. Responsible engineering entails minimal risk to human health and the environment. “We’re always thinking about the balance between economic growth, environmental protection and social responsibility,” Soman concludes. “Smart, multi-functional materials depend on rich collaboration. The more interdisciplinary we are, the better we can tackle today’s challenges.”

–by Rob Enslin